Diesel truck maintenance is a highly contentious topic, mainly because it is so dependent on the type of truck, how it is used, and the quality of the parts that go into it. Whatever the case may be, it needs to be done and a lot more regularly than the dealership recommends. Here’s the maintenance schedule we have found works best for a variety of different makes/models/driving conditions over the nearly 10 years we have been in business.

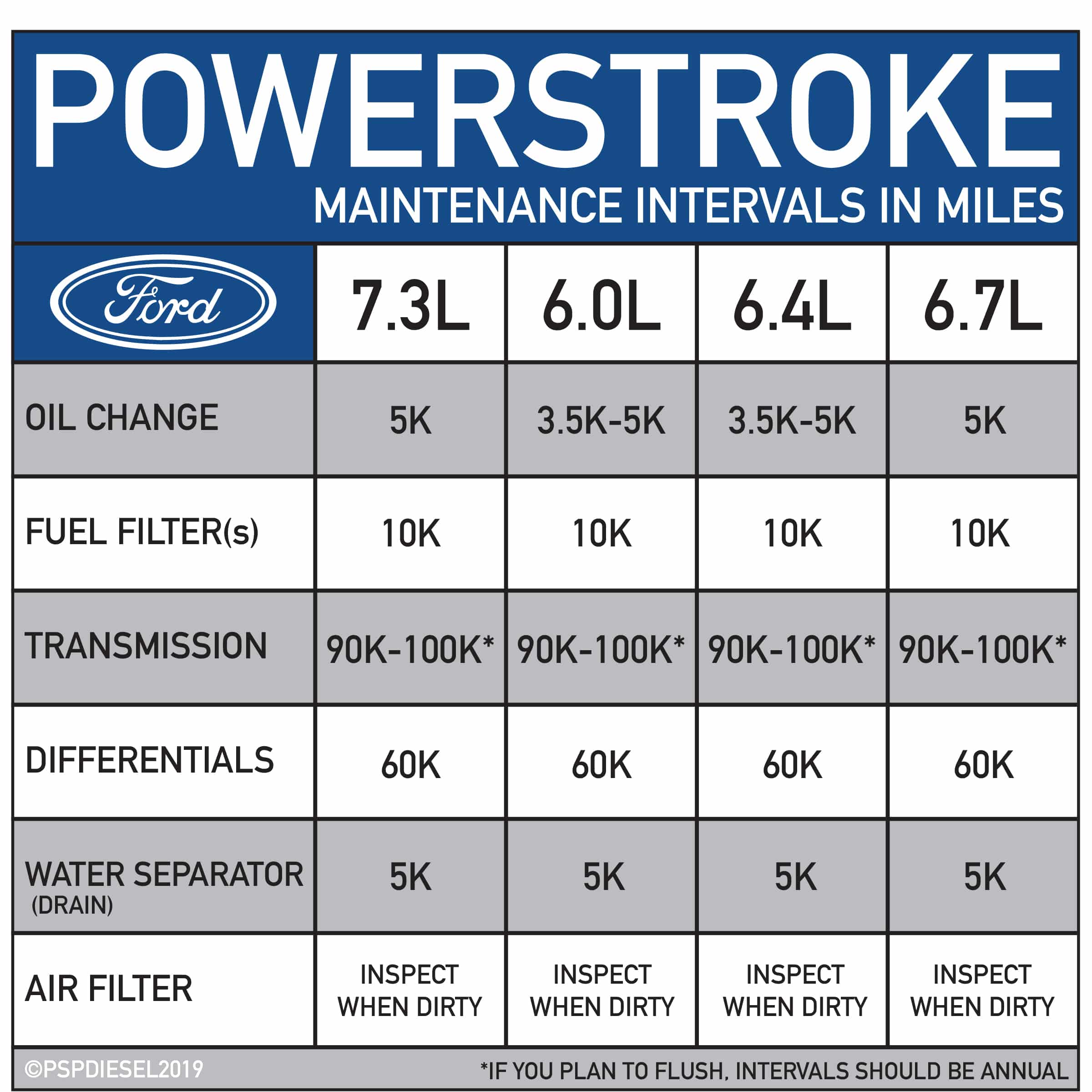

Powerstroke

7.3L

Maintenance, what’s that?!? Yes, the 7.3L Powerstroke is legendary in it’s durability, but it still needs regular maintenance if you want to get that million mile motor sticker. We recommend 5K mile oil changes, 10K miles fuel filter changes, 60K mile differential services, and 90-100k mile transmission services. Air filters should be inspected regularly and changed when they appear dirty. As with other trucks, if you aren’t doing transmission flushes every year, we don’t recommend doing a flush at all; just a drain, filter change, and fill

6.0L

The 6.0L gets a bad rap, though opinions are quickly changing over the past 5 years as the motor has been used for many affordable, very high horsepower builds. From stock to race ready, the key behind this engine is a religious maintenance routine. Because of the inherent issues with the lifters, we highly recommend 3,500 mile oil changes, though these can be pushed to 5k with a good synthetic oil. We have found across the board, from servicing thousands of these trucks and owning a few ourselves, that a 3k-3.5k mile oil interval is excellent for long term durability. BOTH fuel filters should be changed every 10,000 miles, with 60k differential services and 90-100k transmission services. As with other trucks, if you aren’t doing transmission flushes every year, we don’t recommend doing a flush at all; just a drain, filter change, and fill. The air filter should be inspected regularly and changed when dirty.

6.4L

Like the 6.0L, the 6.4L suffers from the same common lifter failure. Due to this weakness, we also recommend 3k-3.5k mile oil changes on this motor. Fuel filters become more critical on the 6.4L due to the introduction of a high pressure fuel system. It’s sensitivity to contamination from dirt or water can range from a no start condition to the complete destruction of the fuel system. The high pressure fuel pump relies on the lubrication in the diesel fuel to run properly. When dirt or water compromise this lubrication, the pump can run “dry” and basically eat itself up, throwing metal through out the entire fuel system. That means a major repair and significant expense for owners, much more than changing their filters regularly. BOTH fuel filters should be changed every 10,000 miles, with 60k differential services and 90-100k transmission services. As with other trucks, if you aren’t doing transmission flushes every year, we don’t recommend doing a flush at all; just a drain, filter change, and fill. The air filter should be inspected regularly and changed when dirty.

6.7L

Oil changes should happen every 5k miles on the 6.7L. A common issue most 6.7L owners face is the infamous “typewriter” noise that often occurs immediately after an oil change. This sound does not relate to any deficiency in the engine, so don’t immediately freak out and pull your hair out over an expensive repair. In fact, this noise is often present in previous Powerstroke engines, but the overall low volume of the 6.7L makes this noise appear much more prominent. Most sources attribute this noise to the incredible tight tolerances in the motor and how different weight/compositions of oil penetrate and interact with those areas. If the noise doesn’t go away after 1000 or so miles, we recommend trying a different type or weight of oil if the noise bothers you. Like the 6.4L, fuel filters are incredibly important on the 6.7L. The high pressure fuel system is sensitive to contamination from dirt or water can range from a no start condition to the complete destruction of the fuel system. The high pressure fuel pump relies on the lubrication in the diesel fuel to run properly. When dirt or water compromise this lubrication, the pump can run “dry” and basically eat itself up, throwing metal through out the entire fuel system. That means a major repair and significant expense for owners, much more than changing their filters regularly. BOTH fuel filters should be changed every 10,000 miles, with 60k differential services and 90-100k transmission services. As with other trucks, if you aren’t doing transmission flushes every year, we don’t recommend doing a flush at all; just a drain, filter change, and fill. The air filter should be inspected regularly and changed when dirty.

For all Powerstrokes, a good coolant flush should occur every 100k or when any fluid/particulate contaminate is present.

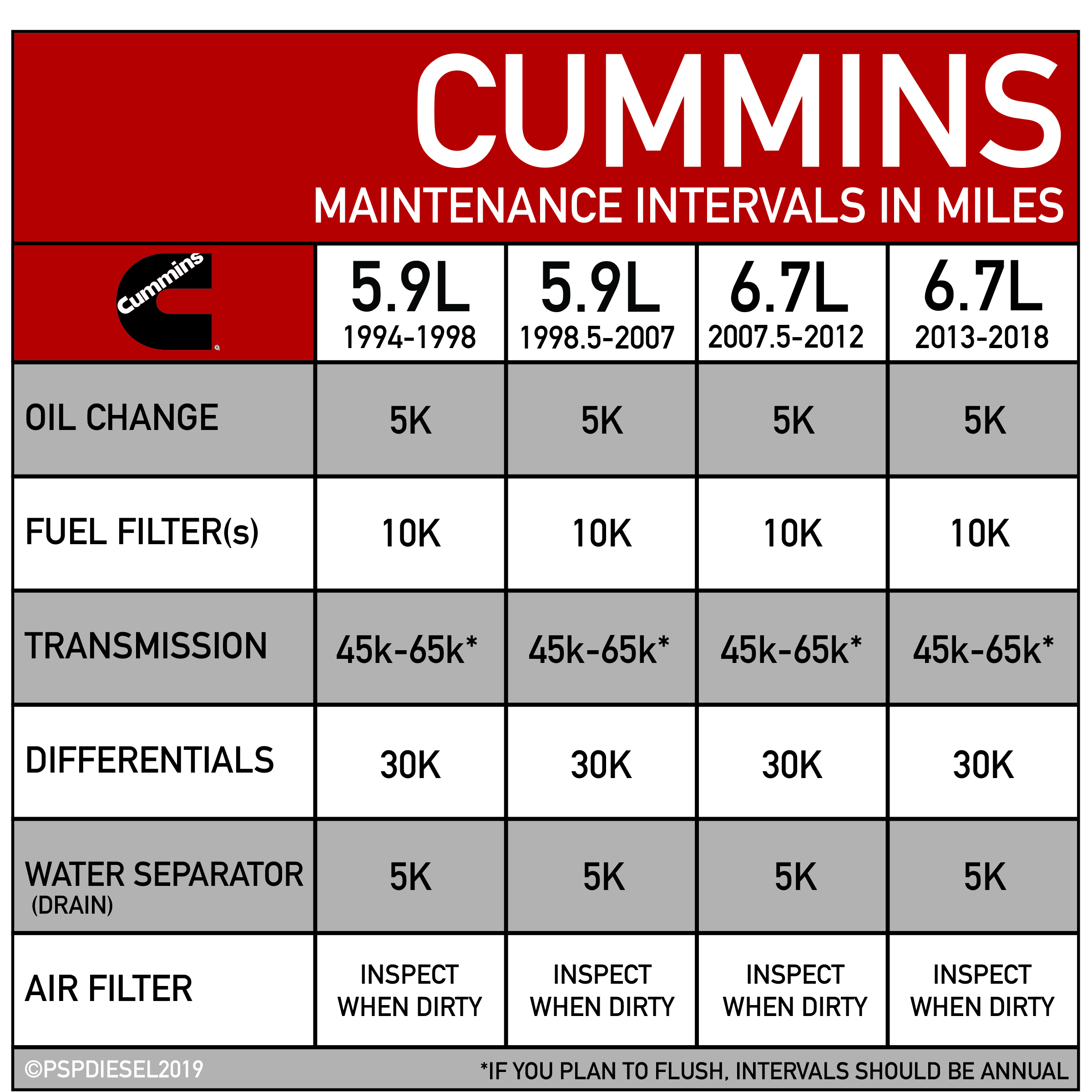

CUMMINS:

The Cummins motor has gained it’s legendary reputation for a reason. In any iteration, it’s a well designed and incredibly robust motor that has taken abuse since the company’s inception in 1919. When considering maintenance, though, we have found very similar standards to the Powerstrokes concerning the oil and fuel work well; 5,000 mile oil changes, 10,000 mile fuel filter changes. On the 6.7L, we would add in a crankcase filter change at approximately 65k, or when the service message requires it.

Moving beyond the motor, though, Dodge doesn’t have the best reputation for things like drivetrain. Though the 47RE and 48RE don’t have the horrific reputation of the later 68RFE, they still require more frequent maintenance than the ‘strokes. We recommend a 45k to 65k transmission service interval across the board, with 30k differential services. If you are rocking the Aisin AS69RC, this interval should work as well, though you may want to bump it down to the 30k-40k range.

The Cummins motor utilizes a high pressure fuel system, so fuel quality is incredibly important. Not only does this include regular fuel filter changes at the above mentioned 10k miles, but make sure you are draining your water separator every 5k miles to ensure it is not full, and thus pushing water toward your fuel system.

A good coolant flush should occur every 100k or when any fluid/particulate contaminate is present.

Finally, we recommend checking valve lash every 100k, or when any performance modifications have been made to your motor, especially any head or cam work.

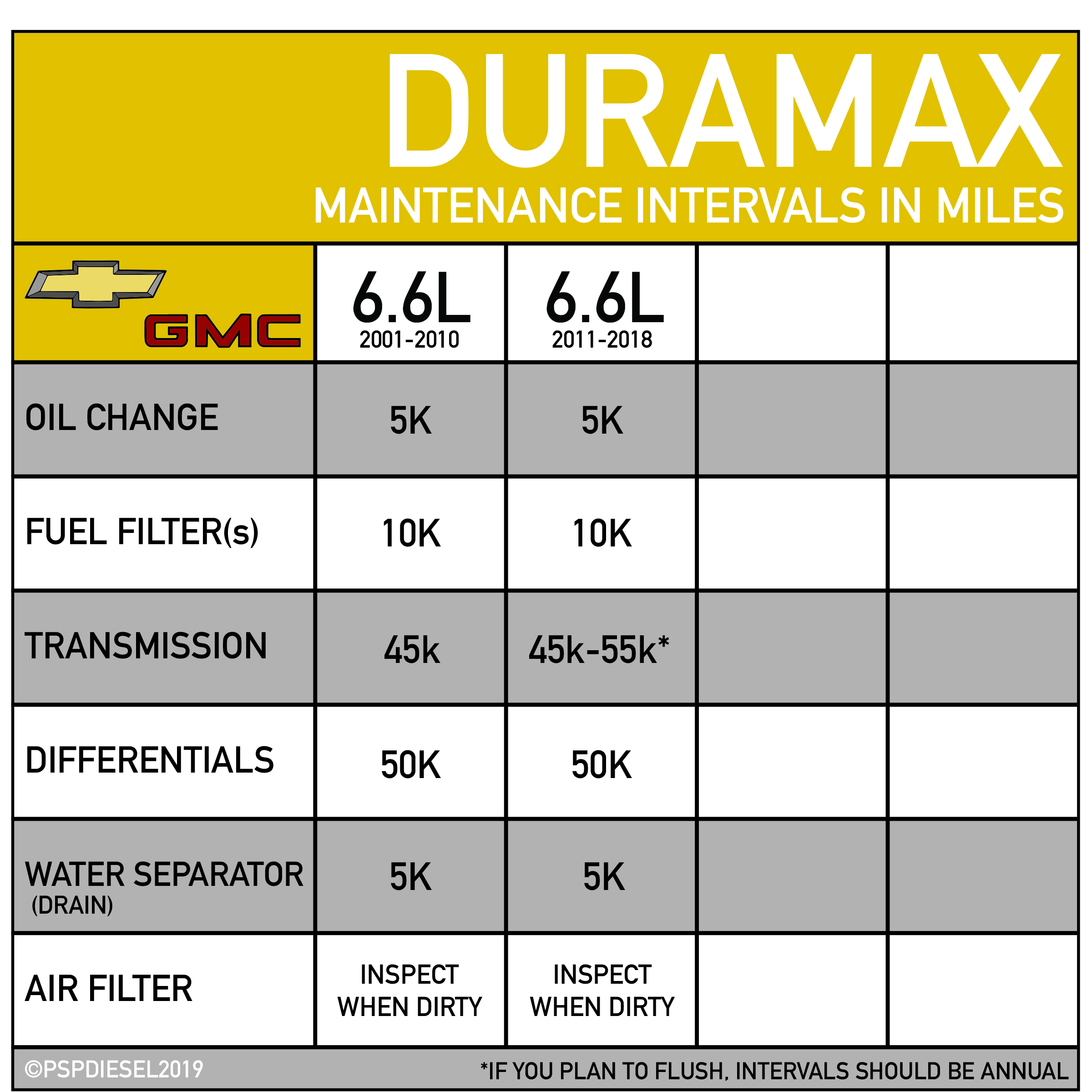

DURAMAX:

Though GM has ridden the 6.6L train from the beginning, (excluding the 6.5L that most people have never even seen), the various iterations have significant differences between them. When it comes to maintenance, though, the above schedule has shown excellent long term results spanning the nearly 20 years of the Duramax 6.6L motor.

Many dealerships, and the manufacturer in fact, advocate for 10k mile oil changes, but we have found this is just too long for the typical usage we see with these trucks. 5k changes have worked well for our customers, so we’re sticking with that.

The Duramax utilizes a high pressure fuel system as well. This system is sensitive to contamination from dirt or water, which can can cause anything from a no start condition to the complete destruction of the fuel system. The high pressure fuel pump relies on the lubrication in the diesel fuel to run properly. When dirt or water compromise this lubrication, the pump can run “dry” and basically eat itself up, throwing metal through out the entire fuel system. That means a major repair and significant expense for owners, much more than changing their filters regularly. The GM platform is the only one out of the big three that still doesn’t utilize a lift pump to relieve pressure off of the volatile CP4 pump, thus exposing the system to even more risk. An aftermarket lift pump should definitely be considered to alleviate this weakness, an added benefit of which is better fuel filtering and water separation.

Transmission services of 45k for the 2001-2010 and 45-55k on the 2012 to newer have proven to work well for long-term durability. Differential services are not explicitly laid out in the manufacturers recommendations, but we’ve found 50k services fit the bill.

A good coolant flush should occur every 100k or when any fluid/particulate contaminate is present.

FINAL THOUGHTS:

In the many years we have been servicing these trucks, I can’t count the times when a proper maintenance routine would have saved customers from some incredibly costly repairs. It’s easy to get busy and forget a service, or balk at some of the higher prices of diesel maintenance services, but when you are staring down the bill of a $10,000 fuel system replacement or motor rebuild, along with the lost work time, that time and money will seem trivial.

As always, if you have specific questions on your truck, please feel free to give us a call, we are always willing to help.

Best,

Stephen

PSP Diesel 713-941-1135